Our lives surf on the achievements of the past while considering endless opportunities ahead. From global food production/distribution, highways and computer networks to energy, we enjoy incredible opportunities at every turn - far more than my Grandfather might have dreamed of more than a century ago.

A recent launch event for Patrick McGee's Apple in China offered an opportunity to reflect on several books I've read over the years.

Principles of Scientific Management

by Frederick Taylor [1911], recommended by long time mentor and friend Bill Steinberg:

Essentially, Taylor suggested that production efficiency in a shop or factory could be greatly enhanced by close observation of individual workers and elimination of waste time and motion in their operation. Though the Taylor system provoked resentment and opposition from labour when carried to extremes, its value in rationalizing production was indisputable and its impact on the development of mass production techniques immense. -- britannica.

Ford Methods and the Ford Shops

by Arnold and Faurote [1915]:

Arnold, a correspondent for The Engineering Magazine, grasped the significance in Ford’s work and began a series of articles on the company’s Highland Park factory. After Arnold’s untimely death, Faurote completed and compiled the articles in the 1915 study Ford Methods and the Ford Shops. The book’s detailed descriptions, numerous photographs and careful diagrams give us a vivid window into Highland Park at a seminal moment in manufacturing history.

Looking back now, the most remarkable aspect of Ford Methods and the Ford Shops is the liberal level of access Ford gave to its authors. It is difficult to imagine Google or Apple opening their doors to today’s press and giving unfettered access to employees, workspaces, and sensitive production figures. The company’s cooperation speaks volumes about Henry Ford’s confidence in Highland Park. He knew that his methods were far ahead of his competitors, and there was little fear of them catching up too quickly. -- The Henry Ford.

Out of the Crisis

by W. Edwards Deming [1982]:

Out of the Crisis is a classic of the quality movement that the Toyota Production System was borne out of. Deming was really one of the founders of that movement and one of the first people to somewhat intuitively grasp the complexity of modern businesses and what that required from management to adapt.

Though this book is clearly directed at physical manufacturing businesses, it’s pretty easy to see how they apply to pretty much any business.

A simple but profoundly true example:

Defects are not free. Somebody makes them, and gets paid for making them. -- Taylor Pearson

## A thankful child of entrepreneur parents, I learned a great deal about the systems behind Deming's work while selling lawn mowers and small tractors in high school and college. A mechanic colleague told me he was shocked that when assembling the first Japanese manufactured Kubota tractor, all the parts just fit, unlike our domestically produced products.

Kaizen

by Maasaki Imai (also recommended by Bill) [1986]:

The oil crisis in the 1970s was a turning point for many businesses in the West when they realized that Japanese companies coped much better than they did during this period of turmoil. The competitiveness of Japanese companies intrigued many senior management teams outside of Japan; some even suspected Japanese businesses had a magical, mystical or mysterious way of operating.

However, the history of Toyota Motor Corporation clearly shows that methods of continuous improvement have been developed over many decades. After studying these practices, I was convinced about the transformational power of continuous improvement as a systematic methodology – KAIZEN™. Due to my unique insight and experience, I saw the opportunity to introduce KAIZEN™ to the rest of the world. -- Imai interview

The Machine That Changed the World

by James Womack [1990]:

Now reissued with a new Foreword and Afterword, Machine contrasts two fundamentally different business systems — lean versus mass, two very different ways of thinking about how humans work together to create value. Based on the largest and most thorough study ever undertaken of any industry — MIT’s five-year, fourteen-country International Motor Vehicle Program — this book describes the entire managerial system of lean production.

Nearly twenty years ago, Womack, Jones, and Roos provided a comprehensive description of the entire lean system. They exhaustively documented its advantages over the mass production model pioneered by General Motors and predicted that lean production would eventually triumph. Indeed, they argued that it would triumph not just in manufacturing but in every value-creating activity from health care to retail to distribution. -- Lean Enterprise Institute.

Freedom’s Forge

How American Business Produced Victory in World War II by Arthur Herman [2012]:

But what’s interesting is that this division of labor didn’t develop harmoniously and smoothly — there was plenty of jostling between business and government, with Knudsen’s firing being only one small example. Herman relates a case in which Roosevelt’s Secretary of the Interior Harold L. Ickes made a giant list of 70,000 individual cases where Henry Kaiser’s companies had violated labor law. Kaiser simply threatened a publicity campaign against the administration, and Ickes backed off. There are various other examples in the book.

Unions got involved too. There were massive waves of strikes all throughout the war production period. The Roosevelt administration, though initially supportive, eventually had to crack down. But that display of union strength, at a critical time, helped to cement labor’s power and pave the way for the good manufacturing jobs that Americans remember from the postwar boom years (whether that power and those wages were sustainable is another question). -- Noah Smith

Apple in China

by Patrick McGee [2025]:

Patrick McGee reflects on the reasons he began looking into Apple’s history and unusual trajectory to majority market share in the U.S. He aimed to uncover what could possibly derail Apple. McGee says, “everything being made in China was the achilles heel of that company.” -- wsp

A major portion of the book focuses on the time during Tim Cook’s ascendancy to CEO and the challenges he has had to placate both Xi and Trump. He had to continue to affirm his commitment to China,even while conducting a facade about building a new plant in Texas to build computers. Even more disturbing, Cook has had to remove apps from the China app store that the government didn’t like, including popular news sites and VPN products, and eliminate the data privacy policies other iPhone users enjoy. -- Phil Baker

Interestingly, McGee's work is published by KKR owned Simon and Shuster, who also released The Machine That Changed the World.

Addressing Apple's unprecedented ability to manufacture and distribute complex products around the globe at immense scale is a worthy topic for McGee and an essential addition to this list.

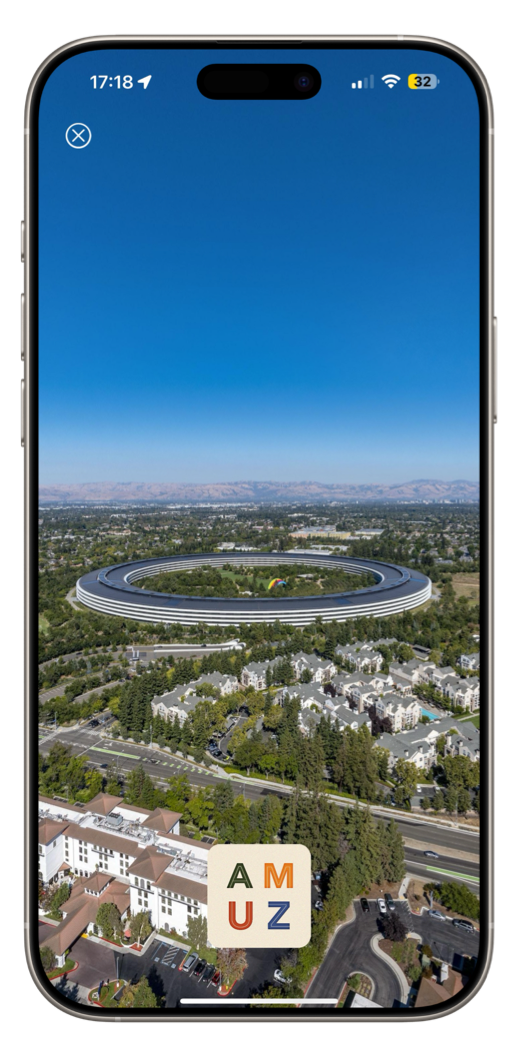

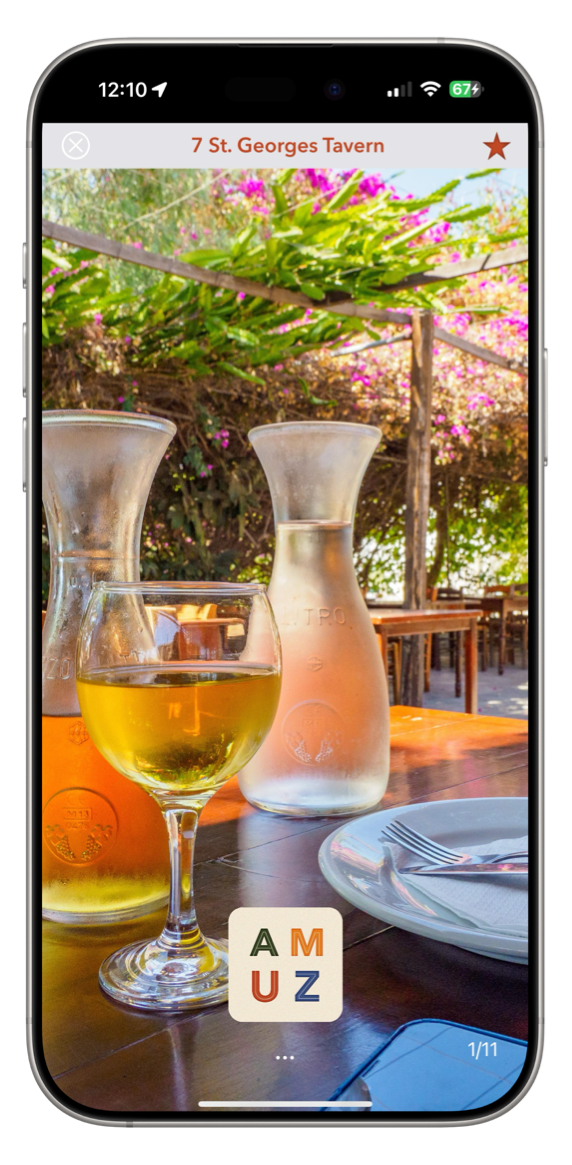

Readers may enjoy exploring places in the amuz app (VR+) such as

Apple Park (Cupertino, CA)

The Toyota Auto Museum (Nagoya, Japan)

The Henry Ford and Greenfield Village (Dearborn, MI)

Starbase (Boca Chica, TX)

BMW welt (Munich)

the Centre for Computing History (Cambridge, UK)

The Computer History Museum (Mountain View, CA)

Tesla (Fremont, CA)

John Deere (Moline, IL)

Kinze (Williamsburg, IA)

the NSA museum (Annapolis Junction, MD)

Bletchely Park (Milton Keynes, UK)

--- Jim Zellmer

You don’t just see this smug complacency, this satisfaction with the status quo and the unwillingness to build, in the pandemic, or in healthcare generally. You see it throughout Western life, and specifically throughout American life. -- It's time to build by Marc Andreessen

How have these books sold? Grok

responds.